Making Tea

The Atherton Tablelands.

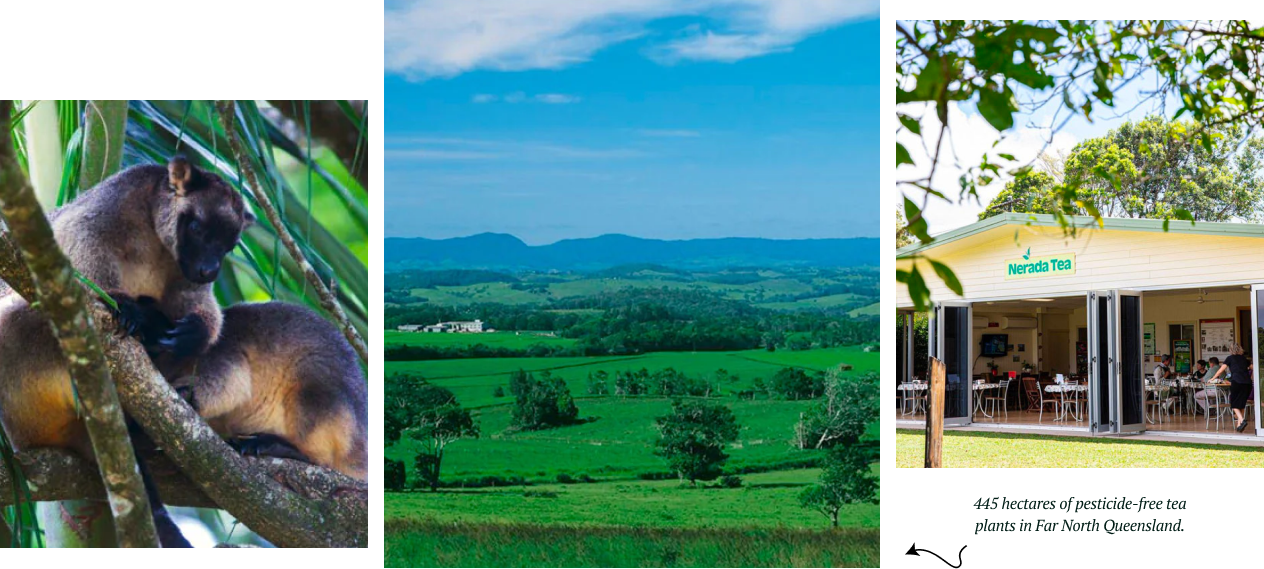

The lush subtropical climate of the Atherton Tablelands provides the perfect environment for making tea.

It’s a special part of the world, boasting a different terrain compared to typical tea-growing regions throughout the rest of the world. Rising more than 700m above sea level, this stunning region of Far North Queensland is one of the most fertile regions in Australia. Its winning combination of rich volcanic soils, high altitude and ample rainfall provide the perfect conditions for growing black tea. Unlike many other tea brands, Nerada is an unblended single origin tea.

The current Nerada Tea Estate is on the top of the Tablelands, near the dairy town of Malanda. Over 1,100 acres, the lush plantation typically harvests more than 6.6 million kilograms of green leaf per year, which makes about 1.6 million kilograms of black tea. It's also home to a rare family of Lumholtz's tree-kangaroos.

We're proud of the fact that Nerada's plantation thrives in harmony with its surrounding environment. Our plantation is not irrigated, sourcing its water from natural rainfall, and our farming methods are completely pesticide-free, both important factors in helping us gain Rainforest Alliance Certification.

Planting & Growing

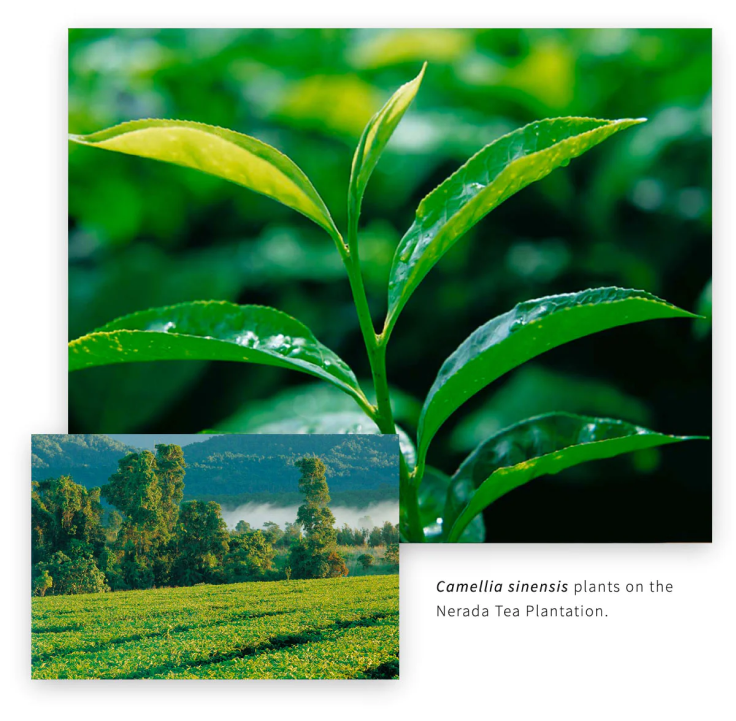

Almost every cup of tea we drink comes from a species of plant known as Camellia sinensis. This remarkable plant produces many of the world’s favourite teas, including black tea, green tea, white tea and oolong.

On the Nerada Tea plantation, plants are grown predominantly to make black tea. It takes about 8 years from planting for the Camellia sinensis to reach its full harvest potential. Only the tender new growth (two leaves and a bud) are harvested to make tea. Due to Australia's strict quarantine laws the tea bush has no natural pests in Australia and hence no pesticides are used in cultivation.

Harvesting Tea

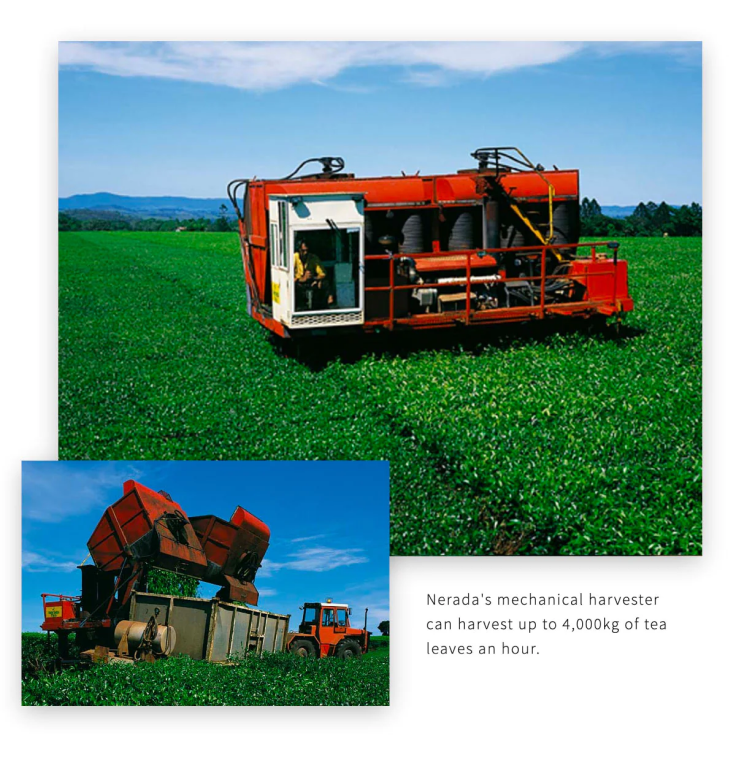

Harvesting at Nerada takes place all year round. Depending on the season, plants are harvested every two to five weeks. We use a specially engineered harvester to locate and carefully remove the most tender leaves and bud from each plant. This tender new growth produces the best tea.

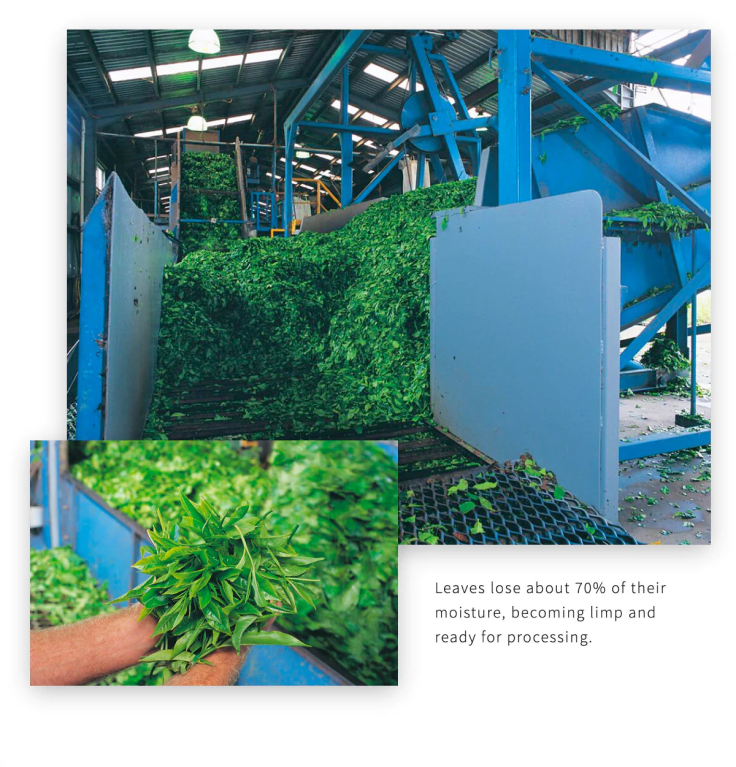

Withering the leaves

The harvested leaves and buds are weighed and assessed for quality, before being placed in specially designed containers with fans to keep them cool. The leaves are kept in these containers for approximately 15 hours and during this time lose about 70% of their moisture content, becoming limp and ready to process. This is called 'withering'.

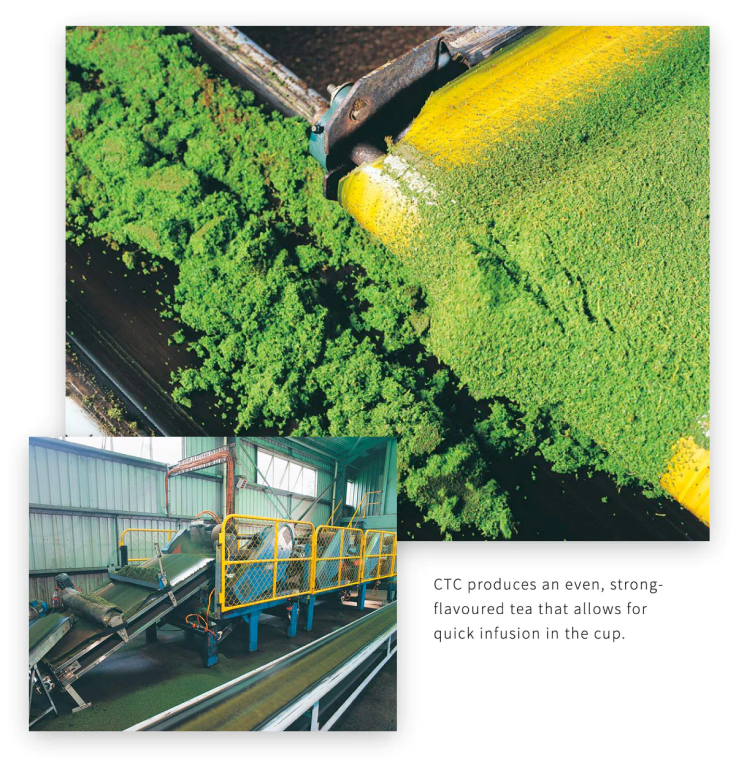

Cut, Tear & Curl

At Nerada we use the Cut, Tear & Curl (CTC) method of tea production, which is used in many tea-producing countries all over the world. The tea leaves are rapidly processed through a series of cutters and rollers to release the juices and reduce them to a moist green pulp. CTC allows for fast brewing and produces an even-sized strong tea that allows for a quick infusion in the cup.

Fermentation & Drying

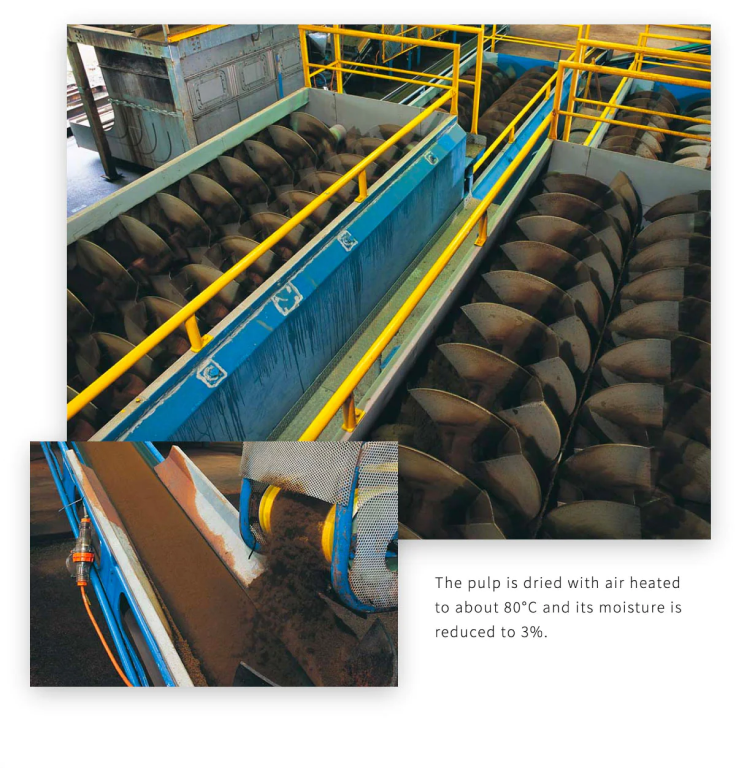

The green tea pulp then moves into the oxidisation process known as 'fermentation'. The pulp travels slowly while being turned and kept cool at all times where it acquires the characteristic tea aroma as the enzymes react with the oxygen in the air. This process takes about 1 hour and 45 minutes and is crucial to the final taste and quality of the tea.

The pulp is dried with air heated to about 80 degrees Celsius which stops fermentation and reduces the moisture content to 3%. This takes about 10 to 15 minutes.

While the tea is still hot from the drier, rollers remove the leaf stalk and fibre with the aid of static electricity.

The Final Product

Once the tea is clean of stalk and fibres the sorting process begins. The tea falls through a series of different-sized meshes to separate the larger tea particles from the smaller ones. It is then sorted into grades, weighed and packed. The larger tea particles are used for loose-leaf packet tea, while the finer particles are used for tea bags.

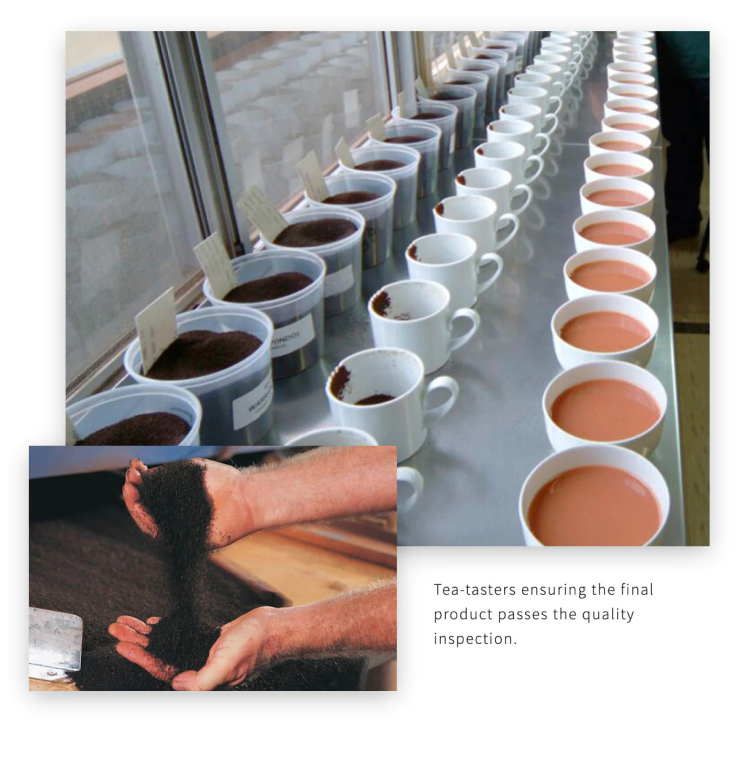

Specialist tea-tasters sample the made teas to ensure Nerada’s strict quality standards are met. The production line is washed down after each run to ensure that it is clean for the next one.

The entire production process, from harvest to finished product, takes less than a day. The tea is then transferred from the Atherton Tablelands to our Brisbane factory to pack and dispatch Australia's freshest black tea.